What is an air-conditioning refrigerant?

In simple terms, aircon refrigerant is the medium that facilitates the heat exchange and keeps your room cool. It can be either a liquid or gas depending on which stage of the process it is at. As the cooled refrigerant passes through the internal air-con unit in your room, it absorbs heat from the air, turns into vapour, and is returned to the compressor outdoors to be compressed. Once the refrigerant returns to the compressor via a series of copper pipes, it is compressed into a liquid state. This cooled liquid makes its way back to the indoor unit, absorbs heat, cools the air and the cycle continues, giving you the comfort of the cool air desired.

Introduction to common refrigerants in Aircon industry – R22, R410A and R32

R22

This is considered the dinosaur of refrigerants coming just after R12 which was its predecessor. R22 is a Hydrochlorofluorocarbon (HCFC) that causes damage to our precious ozone layer. As leakages occur, or when the gas is not disposed of properly and responsibly, the release of R22 into our atmosphere contributes to the thinning of the ozone layer. Due to its negative effects on our environment and relatively poorer heat absorption and release capabilities, it has mostly been phased out.

R410A

R410A (AKA Puron) refrigerant is currently the most used refrigerant in the industry. It absorbs and releases heat more efficiently than R22 thus requiring less energy to cool the air in your room. Due to its ability to release heat more readily, it puts less strain on the compressor. Another perk of using R410A is that it has an Ozone Depletion Potential (ODP) of 0 meaning it does not cause ozone depletion when released into the atmosphere. However, it has a higher Global Warming Potential (GWP) than R22.

R32

R32 is the newest kid on the block. Compared to R22 and R410A it has the lowest Global Warming Potential (GWP), ODP and due to its good heat absorption and release capabilities, is the most energy efficient. One more interesting tidbit is that it is easier to recycle than R410A as it is a single component refrigerant (R410A is made of a mixture of R22 and R125 in equal parts).

Comparison of the 3 Characteristics – Global warming potential (GWP), Ozone Depletion Potential (ODP), and Flammability

|

R22 |

R410A |

R32 |

|

|

GWP |

1810 |

2088 |

675 |

|

ODP |

0.055 |

0 |

0 |

|

Flammability |

Nil |

Low |

Medium |

Global Warming Potential (GWP) is a metric that allows us to compare the global warming impacts of different gases on how much heat they absorb over a specified period. The higher the GWP, the more likely the gas is to cause overall temperatures to rise.

Ozone Depletion Potential (ODP) tells us how hazardous a gas is to the ozone layer. The ozone layer is a thin layer within our earth’s atmosphere that shields us from most of the sun’s harmful ultraviolet (UV) rays. Thinning of the ozone layer allows harmful UV rays from penetrating the atmosphere and reaching us on earth. With more of these harmful UV rays reaching the earth, there is a higher likelihood of contracting diseases like skin cancer, eye cataracts and immune deficiency disorders. It is good to know that the refrigerants currently in use have an ODP of 0!

Flammability of the gases tells you how hazardous it is in general. When choosing between R410A and R32, you might have to take this one into consideration. Though R32 has better heat absorption and release capabilities and a lower GWP than R410A, it is more flammable than R410A.

Existing industry trend and which gases are going to be phased out

With an increased focus on the protection of our environment. Singapore will be implementing a host of new initiatives to encourage manufacturers and consumers to put a focus on greener solutions.

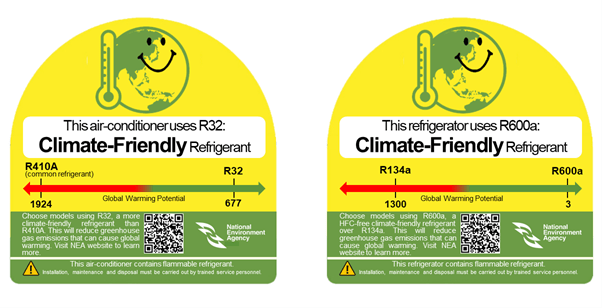

At present moment, the old R22 has mostly been phased out, outperformed by R410A and R32, in both ODP and GWP as well as its primary function as a refrigerant, to absorb and release heat effectively. R410A is currently the most used refrigerant in the air-conditioning industry. However, as we continually strive towards greener solutions, R32 with a GWP of 675 as compared to R410A of 2088 is the clear choice.

But is that enough? Of course not! Even with refrigerants that are greener, they still pose a risk to the environment if installations are not properly conducted and leakages occur. It is also harmful to the environment if these refrigerants are not properly disposed. To prevent this, NEA is working with the Institute of Technical Education (ITE) and Temasek Polytechnic to introduce training courses for household air-conditioner and chiller technicians. In conjunction to training, NEA will be mandating the recovery and reclamation or destruction of spent refrigerants in decommissioned residential air-conditioning equipment. Recovered refrigerants that are passed to the licensed refrigerant treatment facilities can either be reclaimed and re-introduced into the market to service more residential air-conditioning equipment or destroyed using established destruction technologies to ensure proper management of the spent refrigerants.

Conclusion and Future of refrigerants

As we take each step toward cleaner and greener solutions for the HVAC sector, we are also taking steps toward reaching our climate goals pledged under the Paris Agreement. Very soon R410A will join R12 and R22 in the history museum of phased out refrigerants and R32 will be the commonplace in all household.

Here at Infinity Air, our very own inhouse team are already onboard and have completed the training courses for the proper handling of R32 gas. We look forward and will continue to play our part in bringing Singapore toward its 2030 climate goals of a greener nation.