Not many people get to observe an aircon installation happen firsthand. The few times you get the chance to do so would be when you are renovating a new home or replacing an existing aircon after approximately 8-12 years, which is the average lifespan of a unit. To keep you informed and prepared, we will be outlining the steps in an aircon installation, the materials involved and some tips to facilitate a smooth aircon installation in your space.

Pre-Installation: Things to Consider and Plan Ahead

Proper planning is crucial to having an installation done right. Doing some work in advance will save you time, money, and effort. Here are some of the factors to take note of and consider:

HDB Electrical Loading

HDB blocks that have been completed from 1 January 1994 onwards have been provided a higher electrical loading – 40amps main switch. If your HDB was completed before 1 January 1994, then you will be required to apply for a permit before installing any new 15-amp power points or 20-amp isolator for the air-conditioners. For more information, you can visit HDB’s official website here.

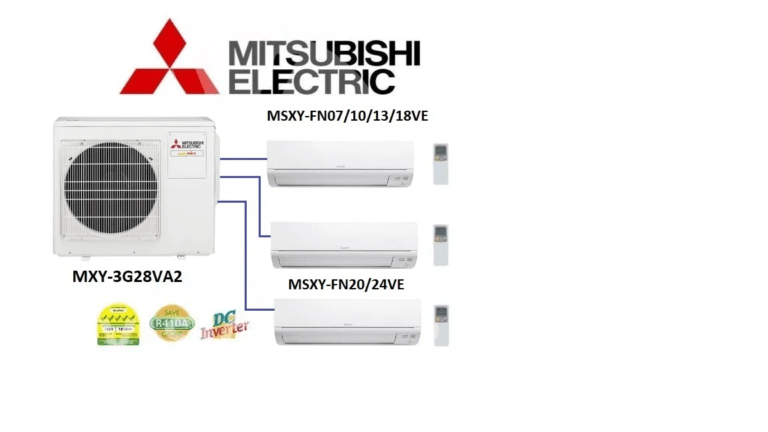

Size of Air-con

Choosing the right cooling capacity for your aircon is essential to allow maximum comfort in the area it serves. One of the key factors to consider is the size of your room, type of insulation and other appliances that can generate heat within the room. You can try out our BTU calculator to give you an estimated gauge.

The standard sized units in the industry are usually 9,000Btu/h, 12,000Btu/h, 18,000Btu/h and 24,000Btu/h for wall mounted units. For more information on the brands and types of air conditioners available, you can visit our installation page. There is a non-extensive list of models listed but feel free to contact us directly if you have other models in mind.

Aircon Placement

Placement of the aircon within the room is key to optimizing cool air circulation and efficiency. Placing the aircon unit at a shaded area will allow your aircon to have an ‘easier’ time cooling the room and avoid condensation issues. Curtains and blinds also play a factor in reducing the heat by blocking the sunlight from coming in on a hot sunny afternoon.

Budget

When planning for the budget, remember to account for maintenance and servicing to ensure that your aircon is running smoothly all-year round. Regular servicing of your aircon should be conducted at least twice a year if not quarterly. For more information on the types of servicing available and the costs involved, you may visit here.

Aircon Installation Material Types

If you have a reliable aircon contractor for your installation, you can probably skip this section. If you are curious, you can read on and find out the types of materials that will help prolong the lifespan of your aircon, reducing the risks of improper insulation or leaks that could lead to costly repairs and unnecessary disruptions. It is always good to check with your aircon contractor on the types of materials they are using and reference with the following:

Piping Insulation

These insulated rubber tubes help to insulate the refrigerant piping so that condensation does not occur from the difference in temperature between the air and pipes. The thicker the insulation, the better it does its job at preventing condensation, which will reduce the risk of faulty leakages. Aircon piping is expensive to redo given the cost of materials and manpower. Thicker insulation will be advisable to minimize the risks.

The industry standard for insulation would be 3/8” and it can be upgraded to 1/2″ insulation for even more peace of mind.

Copper Pipes

These copper pipes connect and transfer refrigerant gases between the fan coil unit (indoor aircon unit) to the compressor (outdoor unit). The thickness of the walls of these pipes relate directly to its ability to withstand refrigerant pressure. The thicker the copper pipes, the stronger it is to withstand more pressure. If there is a gas leak, you will have to either change your condenser or re-run your aircon piping, both of which would be costly to do. Having a thicker copper pipe that can withstand higher gas pressure can help to prevent and minimize the risk of leakages.

With the minimum standard at 23SWG (standard wire gauge), many aircon contractors typically use 23SWG and it is upgradable to 22SWG. The smaller the number, the thicker the copper pipe.

PVC Drainage Pipes

As the name suggests, these pipes are connected to the fan coil unit (indoor aircon unit) and drain off the condensate that forms during cooling.

The industry standard size would be 13mm (diameter), while it is upgradable to 16mm for a smoother water flow and reduce risk of drainage pipe chokes (which usually leads to aircon water leaks).

Do take note that these pipes should be insulated as well when placed alongside the refrigerant pipes to prevent condensation.

Cables/Wiring

These cables supply power to both the fan coil unit (indoor aircon unit) and the condenser (outdoor unit). Thicker wires can withstand a higher electrical ampere from the circuit board to both the indoor and outdoor units.

The industry standard is 3 core 40 wires, and it is upgradable to 3 core 70 wires.

Brackets

These are used to place and secure your condenser unit outdoors. Do note that stainless steel brackets used must comply to the standards set in the Building Control Regulations.

The industry standard would be steel brackets, and it is upgradable to Grade 303 Stainless Steel.

For BTO or newer HDB flats, ledges come along with the unit and the condenser can be placed there instead of getting a bracket.

Ready to Install Your New Air-conditioner?

After taking into considerations the various pre-installation planning items and installation materials, you will be ready for your new aircon to be installed. Here at Infinity Air, we offer the full range of air-conditioning services from installations, servicing, to repairs. If you are unsure of what to do, or if the above seems a little much to handle, you can always visit our FAQs or contact us for a consultation.